To understand the man-made innovations that were made to reduce your vehicle’s engines shaking, we first need to understand the event that occurs in your vehicle. Read on this article from Philkotse.com for better understanding.

So whenever you start and run your car, you are actually igniting internal combustion processes along with a systemized series of explosions. We say “systemized” because the series of explosions are forceful but controlled and are meant to happen.

The answer to the equation, which is the engine vibrations

The second event that happens in your engine is tons of timed pumping, rotating, whirring along with a lot of movements from the internal assembly parts. These parts are made of varying materials that are usually durable, solid and bulky – therefore they weigh a lot.

Take the whirring and whooshing movements, multiply their process by several thousand times per minute and add it to heavy parts that make up your internal engine assembly. What do you get? The answer to the equation, which is the engine vibrations!

1. Engine Mounts

If you start to notice your vehicle engine exhibiting an abnormal amount of shaking, the first place you should look at is the engine mounts. This part, just like any other wear-and-tear part can show obvious signs of aging.

This may even display signs that show the urgency to replace them immediately.

A worn-out engine mount may have tears, cracks or damages that can often be found on the rubber parts. If the damages with your engine mount are worst, you can usually spot the signs of wearing by mere visual inspection.

If the engine mount is still in good shape, you would have to touch it to feel for scratches and wounds.

The first place you should look at is the engine mounts

However, if you have no idea as to how to detect these damages and what to look for when inspecting your engine mount, we suggest that you consult a certified technician.

There is also another type of “mount” that you should be looking into – the transmission mounts. This works the same way as engine mounts but is located in the transmission area instead.

The transmission mounts insulate the rest of your vehicle and protect it from the shaking and heavy vibrations as caused by the processes that take place in the transmission.

These two mounts would need to withstand enormous amounts of pressure and a lot of vibrations per minute from your vehicle’s internal assembly. This is why you need to make sure that these parts are stiff, sturdy and are always in good shape.

There is also another type of “mount” that you should be looking into – the transmission mounts

>>> Read more: 10 most popular car engine parts that you should know.

2. Crossbars

When it comes to preventing vibrations, we cannot stress enough how important it is to have a solid structure. The solid foundation is also known as your vehicle’s skeleton. If your vehicle is made with a dependable set of a skeleton, it should resist bending, flexing as well as transmitting the annoying vibrations. The crossbars are also referred to as “stabilizers bars”, which depicts the job of the steel parts.

A non-reliable stabilizer bar will exhibit signs of poor quality like rattles, buzzes, and squeaks. So to put simply, a low-quality stabilizer bar won’t be able to do its job properly and you may also look forward to worse problems in the future.

Thanks to heightened quality and excellence in most automobile manufacturers, the chances that you’re buying a vehicle with unreliable “skeletal frame” are kept to a minimum. However, you may have a problem if you’re buying a used vehicle from a complete stranger.

The crossbars are also referred to as “stabilizers bars”

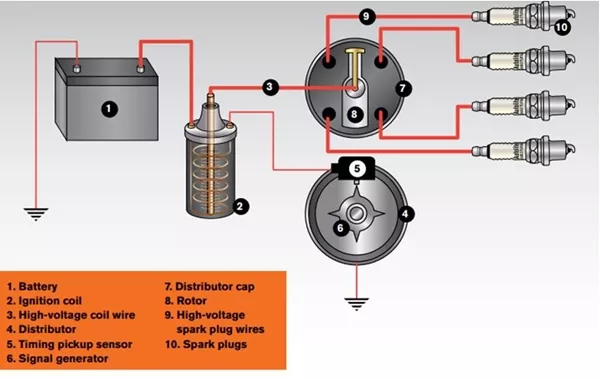

3. Ignition Components

The application of ignition components does a lot for withholding the misfires that happen inside the vehicle. The modern components that make up a lot of the ignition systems in today’s vehicles are usually made up of great-quality sparkplugs along with intelligent engine management computers.

Automakers continue to produce better versions of these elements with more power and capability every year. Curious as to how the ignition components help in preventing or at least minimizing the vibrations produced by your engine? Read below:

Misfiring may happen even if you have the newest and most expensive automobile out there. When a misfire takes place, one or more sparkplugs in your vehicle will fail to fire and ignite the fuel pulse that it’s programmed to do.

That itsy-bitsy failure happens in the many combustion chambers and can cause a hiccup in the systemized rhythm work of your vehicle’s pistons as well as the crankshaft. This results in extremely noticeable jerking, engine stalling, and vibrations.

The application of ignition components does a lot for withholding the misfires that happen inside the vehicle

>>> Also check: Advantages and Disadvantages of Push Start Ignitions.

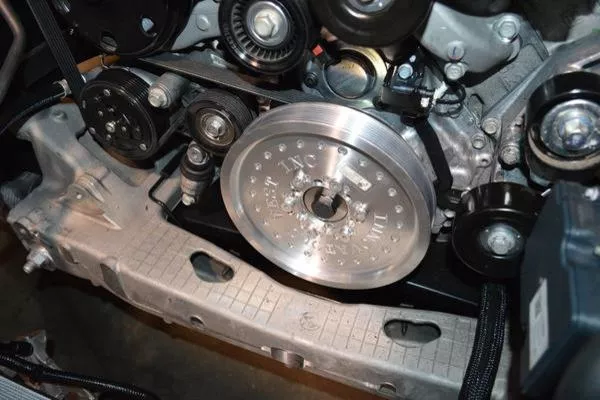

4. Harmonic Balancers

The harmonic balancers are an invention by automotive genius Frederick Lanchester. It is composed of a section that can be made from either rubber material or a particular energy-dissipating solution.

The harmonic balancers also go by many other names like vibration dampener/damper and crankshaft pulley. To understand how this helps the crankshaft, we’ll first try to explain what the crankshaft actually does.

An automobile crankshaft is a chunky and heavy part. It needs to be that way so it will withstand the strong pounding and explosive movements that are coming from the piston. It is also prone to flexing and twisting actions because of the drubbing it receives from the pistons as well as the connecting rods on top of it.

However, at a certain RPM, this can reach the state called “resonance”. This particular state is where the crankshaft vibrates at a supreme frequency which can cause a catastrophe. This is where the harmonic balancers come in to help the crankshaft tolerate the force that’s coming from the different moving parts that surround it.

The harmonic balancers are an invention by automotive genius Frederick Lanchester

>>> Worth reading: How does a timing belt in your car engine work?

5. Active Vibration Control

One of the most effective innovations that keep your engine’s vibrations at bay is the active vibration control. It works similar to a pair of high-tech, noise-canceling headphones with usually ridiculous prices. These types of headsets work by detecting the “noise” from the environment and then duplicate it. It pipes it back to your ears but in a 180-degree position instead.

While the sounds have the same frequency and amplitude, the noises are canceled when its phase was shifted. This is how noise-canceling headsets work and this mechanism is applied to most modern vehicles to minimize the engine vibrations

One of the most effective innovations that keep your engine’s vibrations at bay is the active vibration control

Recent posts

- Engine configurations: A comprehensive guide to different engine layouts Jan 19, 2021

- What are the pros and cons of small displacement engine? Mar 19, 2019

- Can ECU remapping damage your car's engine? Nov 30, 2022

- 5 simple tips to maximum your car engine's performance Aug 16, 2022

- 4 Essential Care Tips for Maintaining Your Car Engine Nov 30, 2022