The engine design of the automobile is constantly evolving since the beginning of the car industry. They become quieter, more durable, less polluting, gain higher fuel-efficiency and become more powerful than before.

Still, engineers are continuously finding ways to improve automobile engines to be used in the future. Before that, let’s take a review on the top 10 engine design improvements ever made in human history brought to you by Philkotse.com.

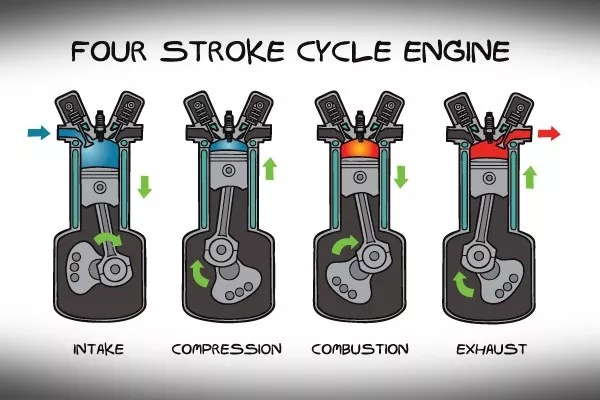

1. Four-stroke Engine Cycle

Four-stroke engine was one of the first improvements applied to internal combustion engines. There are four steps the piston has to complete namely the intake, compression, power(combustion), and exhaust stroke. To complete one cycle, the piston has to make two complete travel along the cylinder.

The operating cycle, on the other hand, needs the crankshaft to revolve twice. This type of engines has numerous benefits like durability, more torque and power, cleaner emissions, and economical fuel.

However, they are more expensive and complicated to make, unlike the two-stroke engine. It also requires the usage of a valve for the exhaust and intake of gases. Despite this, the four-stroke engine still becomes the standard in the car industry.

The four-stroke engine was one of the first improvements applied to internal combustion engines

>>> Read more: 10 most popular car engine parts that you should know.

2. Forced Induction

Forced induction was used primarily on aircraft engines before being used to car engines. The pressure used to deliver the air to the combustion chamber is higher than the usual pressure in a forced-induction engine. This creates more power and higher compression from different engine stroke.

The higher pressure is caused by the turbochargers and superchargers as they are like air compressors that supply more air. Forced induction engine is useful for smaller engines because they can produce much extra power without causing fuel economy to drop or affecting the size of the engine.

One example of this is the Mini Cooper S, which has a 1.6-liter engine only but it creates more than 200 horsepower. Moreover, some high-performance cars also use forced induction to gain more power.

Forced induction was used primarily on aircraft engines before being used to car engines

>>> Related: The beauty of GM's LS engines

3. Fuel Injection

For many years, the carburetor was the common method used in mixing air and fuel and putting it to the combustion chamber of the engine. As time passes by, fuel injection replaces carburetor because of its effectiveness in mixing air and fuel. In the fuel injection system, the gasoline is being injected into the intake manifold where air and fuel are mixed together.

The by-product is then delivered to the combustion chamber through the valves during the process of intake. Fuel injection engines are easier to operate than the carburetors, particularly during cold days. It is also more responsive to throttle changes and more efficient.

Fuel injection replaces carburetor because of its effectiveness in mixing air and fuel

>>> Also check: 4 things you need to know about engine fuel injection.

4. Direct Injection

Direct injection is the modification of the developments made by fuel injection. As the name suggests, it is direct compare to fuel injection which results in more engine efficiency and power. In this type of injection system, fuel is directly sprayed to the combustion chamber.

The computers then ensure that the fuel is burned on proper place and making waste to be reduced. The direct injection produces a leaner fuel mix that burns more efficient. However, it can also exhibit carbon deposits build up on the intake valves, resulting in malfunctions.

Direct injection is the modification of the developments made by fuel injection

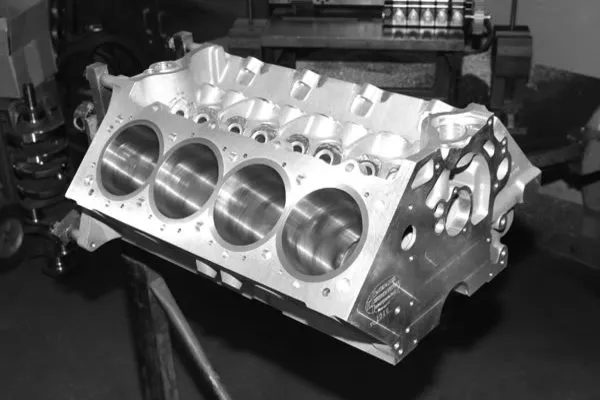

5. Aluminum engine blocks

The automakers are looking forward to ways on how to reduce the weight of the vehicle to provide better performance and fuel economy. A good example of these ways is using aluminum for new small engines.

It is because of its lighter weight that results in better handling and more efficiency. On the other hand, aluminum is not strong just like iron and can’t handle high temperatures.

Aluminum engine blocks have a lighter weight that results in better handling and more efficiency

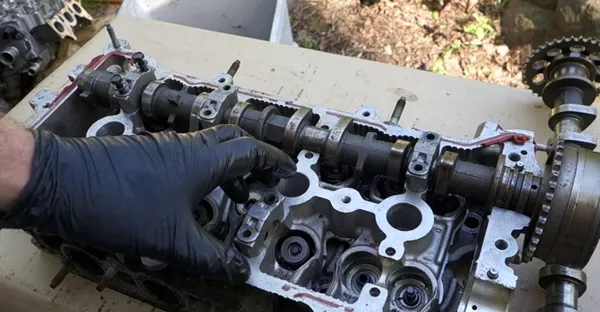

6. Overhead Camshafts

Overhead cam setup permits more exhaust and intake valves, which causes the free movement of air, exhaust, and fuel inside the engine resulting in more power. Also, the camshaft is smaller and is placed directly on top of the cylinder head, not on the engine block. Meanwhile, overhead cams increase cost and complexity.

Overhead cams increase cost and complexity

>>> You might want to know: What does a car engine camshaft do?

7. Variable Valve Timing

Variable valve timing adjusts the flow of air inlet and outlet depending on what is needed. This is very essential to the engine who needs more or less airflow.

This type of engine can give the desired air needed in the operation like for example when hard acceleration, it provides the proper airflow which a traditional engine can’t provide.

Variable valve timing adjusts the flow of air inlet and outlet depending on what is needed

Many engines now are incorporated with a variable valve timing that is particularly controlled by the onboard engine computers.

8. Onboard Engine Computers

The engine is very sophisticated equipment as it contains many moving parts and the occurrence of many processes taking place at the same time. Thus, modern vehicles are now controlled by an onboard computer known as the ECU (engine control unit).

The ECU ensures that the different processes such as air/fuel mixture, idle speed, fuel injection, and ignition timing will function accordingly.

Modern vehicles are now controlled by an onboard computer known as the ECU

It monitors what’s happening in the engine through the use of sensors. It also performs a lot of calculations to keep everything in its operating condition. Engine computers make the engine to operate efficiently than others and easier to diagnose problems. On the other hand, ECU also makes things more tricky and complicated for local mechanics.

>>> Worth reading: 7 must-know tips to extend ECU-based cars' life expectancy.

9. Clean Diesel

The diesel engine nowadays is clean, fuel efficient, and powerful. It is because they use low sulfur diesel oil and systems that help to eliminate excess pollution. Different companies that make diesel engine provide improvements such as fuel injection, turbocharging and computer control to make your driving experience more efficient.

The diesel engine nowadays is clean, fuel efficient, and powerful

However, diesel engines cost higher due to diesel fuel and provide low RPM level. Also, a diesel race car was dominated in the Le Mans races specifically during the last 24 hours.

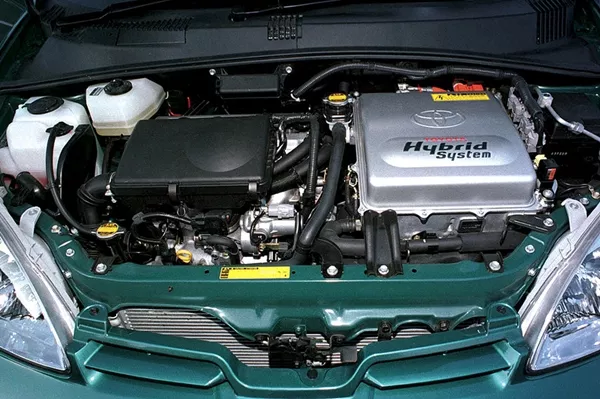

10. Hybrid Engines

The last and biggest engine improvement is the hybrid engine. An electric motor is joined with a traditional engine to attain fuel economy. A good example of a hybrid engine is the Prius which also considered as the newest improvement in the engine technology.

Despite the benefits, there are also some disadvantages of hybrid engines. The initial cost of hybrids is more expensive than the non-hybrid counterparts.

The last and biggest engine improvement is the hybrid engine

Recent posts

- Engine configurations: A comprehensive guide to different engine layouts Jan 19, 2021

- What are the pros and cons of small displacement engine? Mar 19, 2019

- Can ECU remapping damage your car's engine? Nov 30, 2022

- 5 simple tips to maximum your car engine's performance Aug 16, 2022

- Real car deal: 7 Pros & Cons of car Engine control unit (ECU) Jan 19, 2019