The hydraulic system in your manual transmission car is not going to keep functional forever. Just as a lot of items that wear through time, your master cylinder together with your slave cylinder are no exception - they will eventually fail. The slave cylinder which is situated close to the gearbox is notoriously known to be the first to show signs of breakdown.

The hydraulic system in your manual transmission car is not going to keep functional forever

>>> Related: Car clutch: How long does it last and tips to extend its life

In the old days, the method that was popularly used was the clutch cable; today, contemporary cars are utilizing the hydraulic system. For some people who are fans of the traditional method, the clutch cable is still, of course, “the thing.”

But practically speaking, the modernized hydraulic system has a range of advantages. Unlike a poor cable that almost always snaps, the hydraulic system does not fail easily. There are going to be some warning signs that you need to keep an eye on.

Below are the steps on fixing your car’s clutch hydraulic system

1. The things you need:

- Brake

- Fluid

- Clutch master cylinder

- Clutch brake cylinder

- Protection gear for your eyes and hands

- Water and sanitary cloth

>>> Checklist of Essential tools needed in a car tool kit for DIY car maintenance.

2. The level of difficulty

If have been so used to handling socket wrench as well as the ratchet, then obviously, it will be an easy peasy for you. You might even find it fun to work on.

Got everything ready now? Here are the things that you need to do:

Step 1.

The first thing is you have to consider the color. Has your clutch’s color in the reservoir of your master cylinder somewhat changed? If it has turned out to be considerably dark and murky, that is already a sign that it is about to fail anytime soon.

The first thing is you have to consider the color

Step 2.

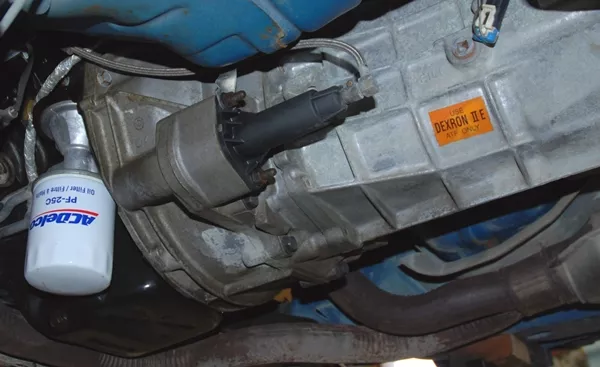

The next thing that you need to do is to find your clutch slave cylinder. Such feature is usually situated on your gear box’s bell housing, just close to the clutch disc along with pressure plate, and your release bearing.

The next thing that you need to do is to find your clutch slave cylinder

Step 3.

Your clutch slave must be undone first. Always make sure that in doing so, you are gentle with your metal clutch’s line and also with the fittings. It is imperative that you do not damage any of those lines. You might expect some fluid leaking from the clutch, so be prepared for that.

Your clutch slave must be undone first

>>> FYI: 6 steps to increase the power of a four-cylinder car.

Step 4.

You might want to bring some bottle, or cups or any container to catch these leaks. You would notice that the drippings are quite filthy and have the color of black.

Step 5.

The next thing that you need to do is have the clutch master removed. Have the clutch line flushed by getting it pumped inside with a clean brake liquid. Consider using a sanitary oil can and a bendable hose.

After this, have the master cylinder installed along with the slave cylinder; always remember to not to get the fittings too tight. Get the reservoir filled with a new brake liquid.

The next thing that you need to do is have the clutch master removed

Step 6.

Allow the clutch system to drain. If you like, you can call a friend, one that is knowledgeable in this, to have the pedal clutch pumped repeatedly.

Step 7.

Then after that, you should firmly hold it down in place. While having the pedal down, get your bleed screw opened in order to let the air out. You should be able to hear it.

Step 8.

Repeat the process, pump and hold (bomba and prime) cycle, ‘til you release all the air out of the system and you are starting to feel the clutch pedal returns.

3. Consider these important things

Clutch hydraulic failure always comes with a warning, it does not simply fail, just like that. If you ever find it quite harder to change into gear, and if it happens that the clutch pedal somehow feels squashy, it is high time to have a thorough inspection of the system.

Besides, look at it closely and see if there are certain issues that call for an immediate response. Grooves that have been worn out with constant use are sometimes the culprit why there is a pressure loss. You should not mistake the whole thing with a damaged clutch disc. That is an entirely different procedure.

Clutch Hydraulic System Air Bubble and Hydraulic Tips

4. Some extra tips

- You can purchase a whole set of clutch repair kit. However, it would be far better if you change the entire assembly.

- Please be informed that brake fluid has been known to be extremely corrosive and it can have a damaging effect on the paint. Always work with extra care. Get it rinsed with water right away once it gets in contact with any painted panel.

- For you to be able to increase the durability of some of your hydraulic parts, you need to have the fluid changed once a year or whenever you notice some ugly discoloration.

5. Fixing a leaky clutch slave cylinder

Step 1: Get the vehicle raised with a jack. Jack stands must be put underneath the frame so that the vehicle can be lowered onto them. You need to trace the pathway of the hydraulic line starting from your master cylinder.

Step 2: The line of fluid supply that is connected to your slave cylinder must be unscrewed and removed. Get the bolts removed as well, the ones that get the cylinder secured to your vehicle’s transmission.

Step 3: Get the snap ring removed from your cast iron cylinder, this is situated at the back of your dust cap. Have the bleeder valve removed and expend a low pressure, you should be able to compress the air so that you could push the piston out of the bore.

Get the bore cleaned using a spray lube. Has it inspected for rust and some pits? It is necessary that you replace it if it is already severely scarred.

How to fix leaky clutch slave cylinder

Step 4: Have the brake cylinder hone attached to the drill and get the cast iron bore honed. This will get the bore cleaned and substantiated to make sure that it is entirely round. Have a new piston assembly installed.

Step 5: Get the dust cap removed along with the snap ring from your slave cylinder. Have the bleeder valve removed too. In general, piston assembly can be taken off from the bore with the absence of compressed air.

>>> Relevant article: Maintenance tips: DIY discovery of bad car clutch plates.

After that, install the cylinder while leaving the bleeder valve open. Has the master cylinder added with fluid? Close it after the fluid starts to trickle from your bleeder valve. Call an assistant to operate your clutch pedal repeatedly and have the pressure kept against it.

Get the bleeder valve opened. The air-fluid mixture should escape. Get the bleeder valve closed and have the procedure repeated ‘til jet of fluid (without the mixture of air) flows. You might want to use some drain pan to catch the fluid outflow.

Recent posts

- How to flush car radiator: Simple hacks save your car Aug 17, 2022

- Step-by-step guide to check and replace a failing car radiator Nov 30, 2022

- A guide with 4 DIY steps to deal with car radiator leak Aug 17, 2022

- 6 Steps to Fix Car Radiator Aug 16, 2022

- Basic care tips for car radiator that every driver should know Aug 17, 2022