It’s no small wonder that car manufacturers are relentless in their pursuit of continuously improving their four-wheeled creations. It’s pretty standard for modern cars to offer small engines packed with performance, cavernous and flexible interiors maximized to the last inch, or state-of-the-art audio and multimedia systems.

We’ve got more cupholders now, more power sockets, more storage bins, more airbags, more rigid safety structures. However, there’s more to a car’s overall performance than speed, space or practicality.

And one part of cars that works particularly hard in daily driving situations isn’t found on the surface, but down below. We’re talking about the suspension system. Keep reading to know more about the car's suspension system with Philkotse.com!

The suspension system refers to the structure that connects the vehicle to the wheels

1. What exactly is the suspension system?

The suspension system refers to the structure that connects the vehicle to the wheels; this connection is not rigid, which allows for a degree of motion between these two components. This setup has the effect of hanging or suspending, the vehicle’s body from the ground, with the intent of insulating it from impacts arising from traveling over a surface.

Why does the suspension need to do this? It’s because of imperfections on the road that can affect ride quality; even a seemingly smooth stretch of road has small undulations or waves that can produce unnecessary vibrations on the frame. These have an effect both on the mechanical aspects of the car e.g. loosening bolts or joints, and the occupants as well e.g. motion sickness and general discomfort.

How does a car suspension system work?

The suspension system has its roots in the old ox- and horse-drawn carriages, where the body of the carriage was fastened by iron chains located on all four corners; this has the effect of swinging the carriage body as it moved along, providing a rudimentary suspension setup that shielded the carriage somewhat from bumps in the road (a big deal has given the absence of paved roads at the time). Eventually, the chains were replaced by leather straps, possibly since the latter was lighter and produced less noise.

However, the straps themselves did not really constitute a true suspension system in terms of absorbing and dissipating the energy of impacts, since all they did was passively suspend the body from the ground. Soon, semi-elliptical springs began to be used on both the front and rear axles of carts, wagons, and buggies. Eventually, the advent of horseless carriages and other powered vehicles gave rise to more sophisticated and efficient suspension mechanisms.

>>> Read more: 3 Bad Driving Habits That Destroy Your Car’s Suspension.

2. What are the parts of a typical suspension system?

The first thing that comes to mind when mentioning suspension systems are the springs, which provide the actual lifting or suspending force on the car’s frame.

The main role of the spring is to counteract the impacts of the car driving over irregularities on the road, as well as to support additional loads apart from the given weight of the vehicle. When a bump causes a wheel to move up, the spring’s action will push it back down, reducing the effect of the bump on the car body.

In current suspension systems, there are at least three types of springs being used:

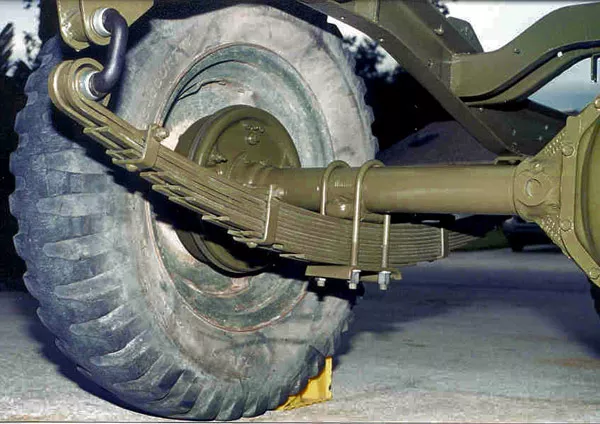

Leaf springs

The springs used as early as the horse-drawn carriages of old. Leaf springs are made from spring steel, a range of metals that possess high yield strength. Objects made of spring steel are able to return to their original shapes despite significant amounts of twisting.

The springs used as early as the horse-drawn carriages of old

Slender strips of spring steel are bent into an arc, with the axle mounted at the center. Loops at either end of the strip allow the spring to be attached to the vehicle chassis.

In some variations, one end of the spring mounts to the vehicle frame while the other end is attached to a shackle, to further soften the spring’s motion. In heavier vehicles, leaf springs are comprised of several strips of spring steel stacked on top of each other, with each strip getting progressively shorter going outward.

Coil springs

Coil springs made of hardened steel, they are coiled around an axis by machine, and possess different characteristics such as stiffness and dampening, depending on the alloy used.

Coil springs expand to support the vehicle’s weight according to its designated height

The coil shape lets it compress to absorb road shock, and then expands to support the vehicle’s weight according to its designated height. It’s the coil spring that actually absorbs most of the impact shock acting on the wheel, while the shock absorber merely slows down or dampens the spring’s compression and rebound motion.

>>> Related: Leaf Spring vs Coil Spring Suspension: What are the differences?

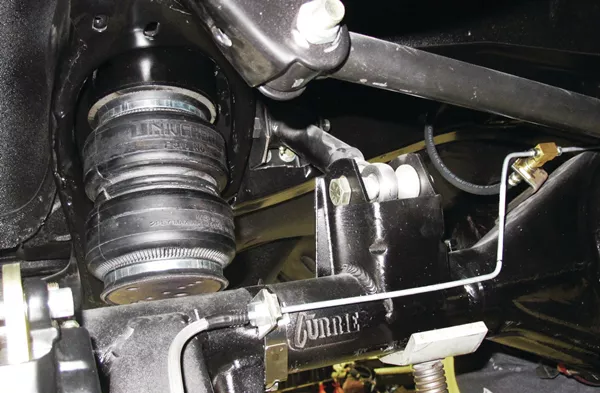

Air springs

Air springs are springs that use compressed air delivered by an air pump, whether electrically or driven by the engine. The air is pumped into flexible bellows made of textile-reinforced rubber. Air springs are commonly found in trucks, buses and other vehicles that require smooth operation and consistent ride quality.

Air springs these are springs that use compressed air delivered by an air pump

They are also extremely adjustable by increasing or reducing the level of air pressure inside the bellows; this allows the vehicle to vary its ride height depending on certain situations.

For example, a bus with air suspension can lower its step height so that passengers can board easily, or increase the ground clearance to help negotiate steep ramps. Air springs are also becoming popular among custom car tuners.

>>> You might want to know: Suspension modifications for city driving & heavy duty in the Philippines.

Shock absorber

Another component of the suspension system is the shock absorber or damper, which serves to slow down the rapid compression and expansion of the spring when negotiating imperfections on the road surface. Shock absorbers use hydraulic fluid to convert the kinetic energy delivered by the impact of thermal energy that can be easily dissipated.

One common characteristic of all shock absorbers is their sensitivity to velocity, meaning the resistance of the shock absorber increases as the suspension moves more. This makes shock absorbers capable of adjusting to various road surfaces and manage unnecessary movement, such as bounce, acceleration squat and sway.

Effects of worn shock absorbers on road safety

Similar in function to a shock absorber is the suspension strut. This is usually found in a coilover design on cars, meaning it incorporates a coil spring and a shock absorber as a single functioning unit. Suspension struts further soften the impact forces acting on the spring, while supporting the weight of the vehicle.

>>> Also read: 5 easy tips to diagnose your car suspension problems.

3. How does the suspension system benefit the car?

One important purpose of the suspension system is to maintain the car’s connection with the road surface. This is important in maintaining traction across a variety of road conditions, as well as keeping the car stable under different load conditions.

When a car accelerates, the momentum tends to shift the weight to the rear. Too much force too soon and the front end will rise sharply, which compromises control since that’s where the steering wheels are located.

When the vehicle stops, the weight is now transferred to the front, which also isn’t ideal since the momentum may exceed the vehicle’s ability to change direction sufficiently to avoid danger. A proper suspension system carefully manages the forces in both scenarios, by keeping the car stable enough to maintain adequate traction on either end where necessary.

A suspension system is to maintain the car’s connection with the road surface

It’s not just in straight-line travel that the suspension system benefits the vehicle. Tackling a corner, especially at high speeds, produces a centrifugal force that shifts all the weight of the car outwards to one side, depending on which direction the curve points. The inside wheels will lose traction, raising them a few inches off the surface.

It’s a perilous situation since it places the car in a position to do undesirable things such as rolls and slides. The suspension system keeps this in check by making sure all four wheels are in contact with the road, to mitigate the effects of the forces acting on the car.

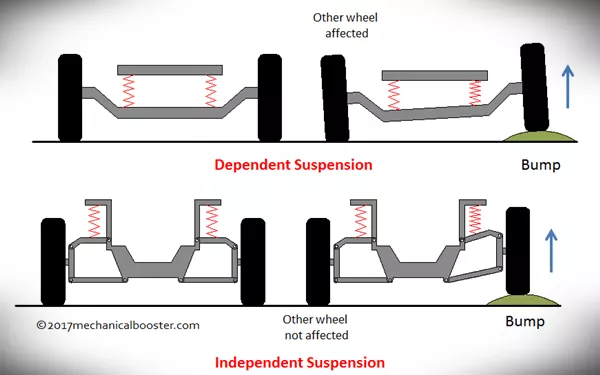

Suspension systems are typically categorized according to the ability of the opposite wheels to move independently of each other. These are dependent, semi-independent and independent systems.

Dependent suspension systems

These usually have simple designs, which translate to lower costs; as such, dependent suspension systems are preferred by backyard enthusiasts and fabricators.

The mainstay of a dependent suspension system is the beam or solid-axle design, a long rigid metal shaft that connects the wheels across the width of the frame. A particular force acting on one wheel will affect the other wheel on the opposite side,

hence dependent.

There are typically two types of beam axle setups: live and dead. In a live axle configuration, the wheels are powered, while in a dead axle, the wheels freely spin. Beam axle setups are common among vehicles that are used in rough terrains, such as SUVs, as well as those that are built to carry heavy loads, such as vans and trucks.

Apart from their simplicity, dependent suspensions also deliver constant wheel camber, which cuts costs even further since there is no need to periodically adjust the wheels as a result of varying payloads.

One disadvantage of dependent suspension systems, however, is the increased likelihood of unsprung weight, or the weight that isn’t supported by the car’s suspension parts; a live rear axle with the differential gearing inside already contributes a significant amount to the vehicle’s overall mass.

This has the tendency to increase every vibration as the vehicle goes over the road surface, as well as present difficulties in terms of wheel control in times of acceleration and stopping.

Suspension type: Dependent and Independent

>>> Grab your attention: Easy steps to troubleshoot car suspension system.

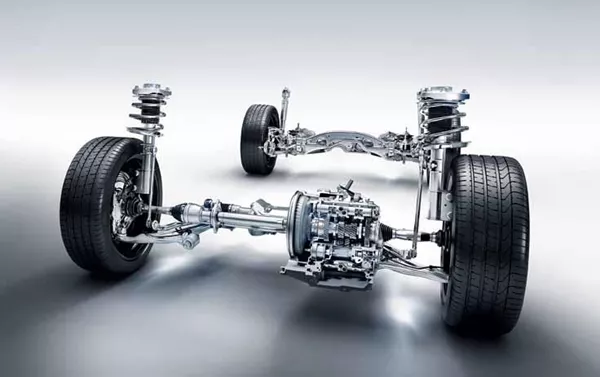

Independent suspension systems

In an independent suspension setup, the wheels on the opposite sides of the frame are not connected by a solid axle. This allows them to move freely, or independently, of each other. Each wheel is designed to move vertically in reaction to an irregularity on the road surface, without having to depend on the other three. The effect of going over a bump on the road is isolated on the wheel directly involved; it does not affect the other wheel at the opposite end.

Whereas dependent suspension systems seem to emphasize load-bearing capabilities, independent suspensions focus on improved ride comfort, enhanced traction, and increased stability, which is why car manufacturers prefer these on passenger vehicles.

Independent suspensions may entail a more complicated design and build, but the result is a smoother ride and improved handling, mainly because of the lower unsprung weight compared with dependent suspension systems. One way that manufacturers achieve this is by bolting the differential unit (for the powered wheels) directly to the vehicle’s chassis using a subframe.

Different types of suspension

The trade-off for independent suspensions is the need to periodically adjust for the camber and alignment of the wheels since there is no rigid axle to maintain the camber. Any deviation from the ideal camber will result in uneven tire wear, eventually compromising handling and control in the long run.

There are several kinds of independent suspensions that are being used in modern cars:

MacPherson strut – popularized by Earle MacPherson, who was chief engineer at Chevrolet in the mid-1940s. This type is widely used in cars today, especially on the front suspension. It features a strut-type spring and shock absorber that work in tandem on a single ball joint. MacPherson struts are commonly found in front-wheel-drive cars.

Double wishbone suspension - this uses two suspension arms (called A-arms or wishbones). One end of each arm mounts to the wheel, while the other end is connected to the frame of the vehicle. The coil spring and shock absorber are also mounted on the wishbone, to better manage vertical movement.

Double wishbones provide a wide range of control over several parameters, such as caster and camber angle, scrub radius, roll center height and toe pattern.

There are several kinds of independent suspensions in modern cars

>>> For your off-roaders: Suspension modifications for off-road goodness in the Philippines.

Multi-link suspension – this uses three or more lateral arms, and at least one longitudinal arm. Occasionally these arms will be of unequal length, with each having a spherical ball joint or rubber bushing at the end.

Multi-link suspensions are capable of flexing to a greater degree compared to other independent suspension types, making them ideal for the varying contours associated with offroad driving. On the downside, multi-link suspensions are complicated to design and build, as well as costly to maintain and repair.

Trailing-arm suspension – somewhat resembles a double-wishbone suspension, this makes use of two trailing arms, the front end of which pivot on the car’s body. Because it is a single-piece assembly, the arms are usually larger compared to those on other suspension systems, with the coil spring supported on the upper surface.

The design is not as flexible in that it only allows for vertical movement of the wheel; variations in lateral movement and camber, at least as far as the car’s frame is concerned, is not allowed. However, the trailing arm is still able to follow the car body’s angle when the car negotiates a corner.

The kind of suspension system used gives a clue as to the intended purpose of the vehicle it happens to be mounted on. But whatever a vehicle will be used for, we can always count on advances in suspension systems to ensure that our rides continue to be stable, comfortable and capable of covering thousands of kilometers along with their service life.

Recent posts

- 9 essential car features that you need to know before taking the wheel Aug 16, 2022

- Buying tips: 3 different wheel types and what you need to know Feb 24, 2021

- 5 things you need to consider when choosing the best wheel size Apr 13, 2021

- Is your car suspension ready for the rainy season in the Philippines? Sep 05, 2018

- 4 drawbacks to bigger wheels Jan 22, 2018